Click to Shop our Motorcycle Fairings!

There are two basic methods for making motorcycle fairings – lets look at compression vs injection molding. They end up with similar products, but the methods to make them are very different.

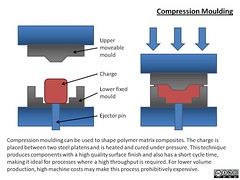

Compression vs Injection Molding

Compression molding is a where molding material is preheated and placed into heated mold. The mold is closed, the compression part, forcing the material to contact the mold. Heat and pressure are maintained until the molding material has completed. Compression molding allows for high-volumes as well as complicated molding projects – like motorcycle fairings.

Injection molding is a process for producing parts (in this case motorcycle fairings) by injecting material into a mold. Material is fed into a heated barrel, mixed, and injected into a mold where it cools and hardens into shape.

The molds are tooled from metal, usually steel or aluminum, and then precision-machined to form the features of the desired part. Injection molding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars.

So which one is best:

Most of the time – injection mold. It is the most accurate and true to original size, about 98% fitment, which is as good as factory. (Which are all injection molded.)

They are a bit more in cost – so if price is a big factor and you have time to fiddle with the fairing and get things perfect, then you may choose compression. Some of the older bikes will only offer a compression mold.